Casting Trophies

Marver set up for casting our own Mt. Begbie.

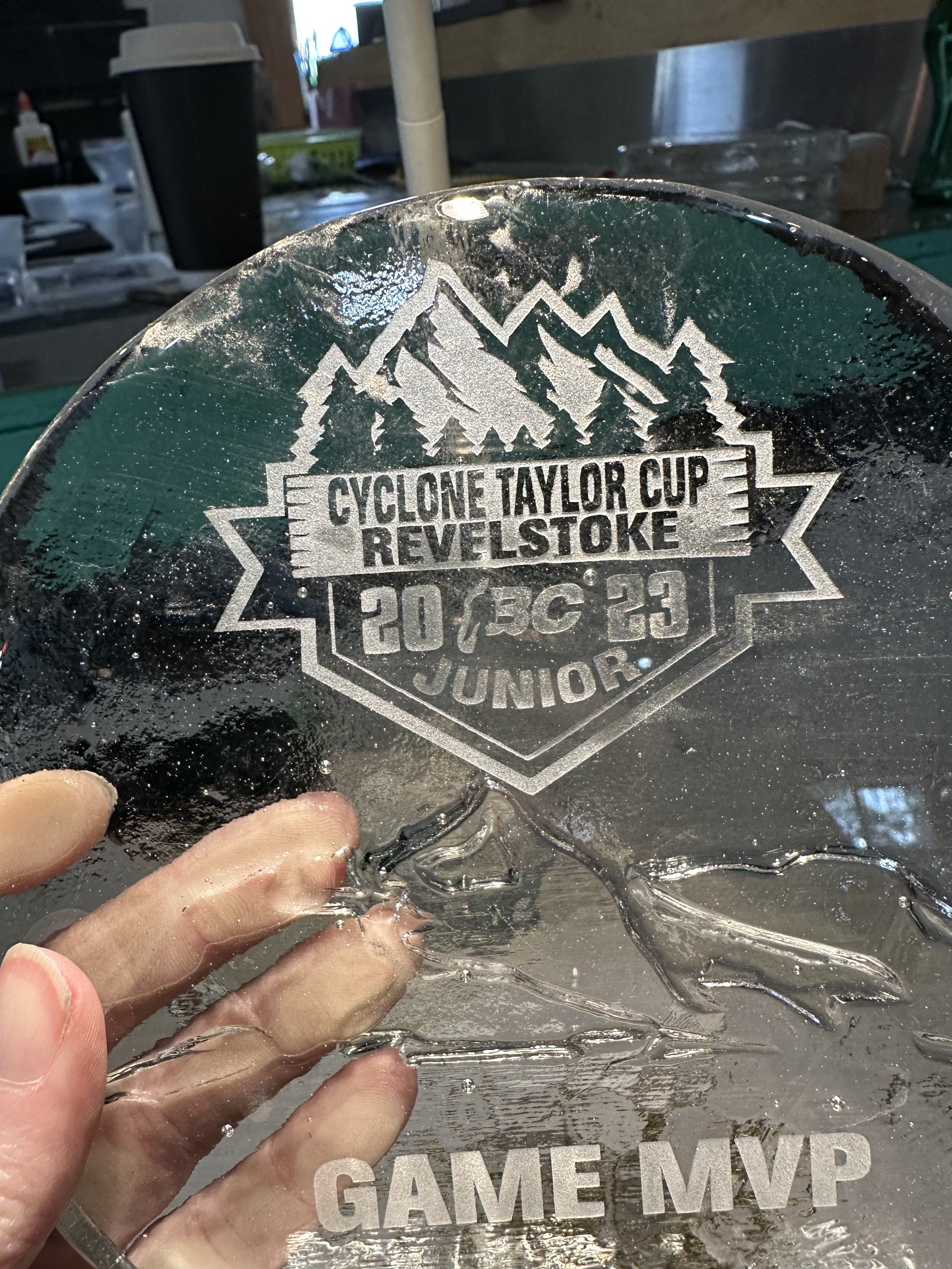

This past weekend (April 13th, 2023) the Cyclone Taylor Cup Championship Tournament came to Revelstoke. This Junior Hockey tournament was won by our very own Revelstoke Grizzlies! Even more exciting for the team here at Big Eddy Glass Works, we were asked to make the Game MVP trophies, something we have never done before!!

After discussing design points with the tournament organizers, and some internal discussions on how we could make these trophies connected to Revelstoke, Leah decided to make a graphite casting mold with the outlines of Mt. Begbie. These types of commissions are so exciting for us, and truly take the whole team to complete. We absolutely love the way they turned out and hope you do too!

Keep on reading for the process of casting, cold working, and sandblasting the Game MVP trophies.

Step 1: Make the Casting Mold

Lucky for us Leah had an existing sheet of graphite, so once she had designed the Mount Begbie outline and made it into a sticker, we were able to sandblast the design straight into the graphite. Then we used an existing steel ring, and a separate section of graphite to create the flat bottom for the trophies to stand.

Step 2: Casting

Once the mold was ready, we turned up our furnace to make the glass even hotter than normal so casting would be easier. Once the furnace was ready, we took a large ladle, scooping out hot glass and filling the mold. Next we use a hot torch to even out any discrepancies across the exposed top. Once the glass has settled, we removed the outer ring of the mold and let the glass cool for another minute before removing it from the graphite and putting it away in our annealer.

Step 3: Cold Working

When the trophies came out of the annealer, we began labeling them with the Cyclone Taylor Cup logo and “GAME MVP” stickers that had been made in advance by Leah. Once the stickers had been properly applied, the entire exposed surface of the glass was covered with thick painter’s tape, with multiple layers around the stickers because this is the region where the sandblaster will be directed.

After the logo and letters had been sandblasted and rinsed with water, we were able to remove all tape and stickers and see the final sandblasted look! Finally, Leah leveled them out using a diamond lap wheel to ensure they stood up solidly on their own.

We were so excited to see these trophies come to life, and look forward to using our Begbie mold on future projects and items!